Add: 585 South of Zhonghua Street, Shijiazhuang Heibei , China.

Tel: +86-311-67260097

Fax: +86-311-67260097

Contact: Jack Cui

Mobile/WhatsApp/WeChat: +86-15354482218

E-mail:sales@feiruitrade.com

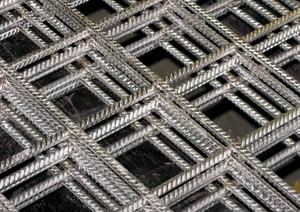

Reinforcing Mesh

• Economic transport;

• Economic transport;

• Ease and economy of storage space;

• Reduction of implementation time (high application performance);

• Installation does not require skilled labor;

• Quality ensured by the implementation in factory;

• Reduction of waste and failings.

Description

Slab Reinforcement Mesh: BASE MATERIAL

• Hot dipped galvanized

• Electro galvanized

• Stainless steel

Slab Reinforcement Mesh: Variety

• Truss-Mesh Reinforcement

• Ladder-Mesh Reinforcement

Slab Reinforcement Mesh: Specifications

Slab Reinforcement Mesh: Specifications

Reinforcing Mesh Sheet Width: 0.5m -1.5m (2 foot -6 foot)

Length of Sheet: 0.5m -4m (2 foot -6 foot)

Opening of Welded Wire Mesh: 2.54cm-20cm (1 inch -8 inch)

Wire Diameter Applied: BWG 18- BWG10 (1.6mm- 3.0mm)

Slab Reinforcement Mesh: Applications

Reinforced Welded Wire Mesh Panels are made of galvanized welded wire mesh for constructional uses, for example, block slab structure reinforcing, hollowed slabs reinforcement, building wall reinforcement and support wall reinforcement.

Slab Reinforcement Mesh: Placing of Fabric

In order to obtain the best results when using fabric reinforcement, special care must be taken to ensure that the mesh is positioned and maintained at the correct depth after the concrete pour. This can be done by using stools or plastic or concrete spacers. Another option is to place the fabric on poured concrete that has been leveled to the desired reinforcement depth. After placing the mesh the concrete can be topped up to the specified overall slab thickness.

Ideally fabric must be located 50mm from the top of the slab and where bottom steel is required,, it must also be supported 50mm above the substrate.